2024/06/07

Revolutionizing Vehicle Transmission Systems with Electric Linear Actuators

News and Articles

Sina, a researcher in the framework of a MARIE-SKLODOWSKA CURIE ACTIONS research fellowship used a TiMOTION actuator, as a research-promoting gift, to develop his Ph.D. thesis. His Ph.D. program was a branch of the mother project entitled LIVE-I. LIVE-I stands for Lightening and Innovating transmission for improving vehicle environmental impacts. Sina developed his research activity at the University of Naples Federico II in Italy and ADAPTRONICA sp. z o.o. in Poland. He finally concluded his thesis on 28 Feb 2024.

The Challenge, Enhancing NVH Performance in Gearboxes

The Ph.D. project aims at mitigating vehicle gearbox noise and vibration using a semi-active control solution. The semi-active solutions are a compromise between active and passive solutions. Sina used metal rubber to realize the semi-active concept. By pre-compressing metal rubbers, various levels of stiffness and damping can be achieved to generate the control levels.

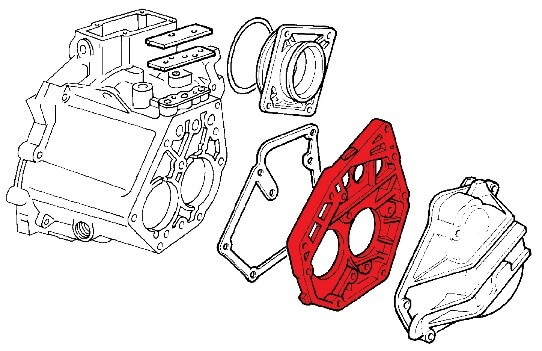

Figure 1. An explosion view of a Fiat manual transmission casing

TiMOTION's Electric Actuators at the Heart of Innovation

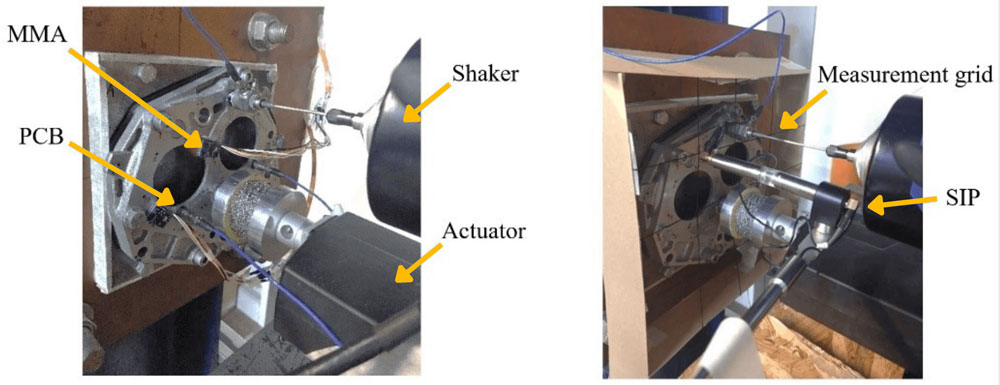

TiMOTION Europe graciously provided a TA29, a meticulously chosen linear actuator whose specifications seamlessly aligned with the project's demand. While the integration was relatively smooth, minor hurdles surfaced, including issues with the actuator's pinout description and operational bending moments. However, the team's ingenuity prevailed, overcoming obstacles through bracket modifications and a dual-control strategy integrating hall sensor and time-based controls.

Promising Results for Semi-Active Vibration Control

With the TA29 at its helm, the project not only met but exceeded expectations. The semi-active isolator, a testament to innovation, showcased remarkable results. Phase one unveiled a 55% reduction in vibrations, while phase two witnessed a commendable 28.71% and 23.57% attenuation in vibration levels through open-loop and closed-loop strategies, respectively. Furthermore, an overall acoustic isolation rate of 25.03 % and 19.98 % is achieved through the open-loop and closed-loop strategies, respectively. These findings underscore the efficacy and promise of semi-active solutions in automotive NVH control.

Figure 2. Test setup: (left) vibration measurement, (right) noise measurement.

Conclusion

In summary, this project offers an innovative semi-active solution for vibration attenuation in vehicle transmission systems. By leveraging linear electric actuators like TiMOTION's TA29, combined with advanced control strategies, significant improvements in NVH performance can be achieved.

This approach opens exciting new perspectives for the development of quieter, more comfortable automotive transmissions. Electric actuators thus emerge as a key technology to address the vibrational and acoustic challenges of the modern automotive industry.

Feel free to contact us to learn more about our linear electric actuator solutions and discover how they can revolutionize your projects.