Le nouveau vérin industriel MA4 a été spécifiquement conçu pour les applications devant faire face aux environnements difficiles et qui nécessitent performance et durabilité.

Cette nouvelle génération de vérin dispose en option d'un système innovant intelligent avec contrôleur embarqué.

Cette technologie permet de coupler et de synchroniser jusqu'à 8 vérins. Sous le principe principal/secondaire et grâce à l'échange bilatéral de données, le vérin principal est en effet capable de contrôler 7 vérins secondaires, et ce, sans nécessité d'ajouter de boîtier de contrôle pour plus de facilité d'installation.

Les utilisateurs pourront ajuster de manière indépendante leur système à partir d'un ordinateur grâce au PGMA, logiciel développé par TiMOTION, mais aussi accéder à de nombreuses autres fonctionnalités :

- Programmation de la synchronisation

- Ajustement de la course et de la vitesse du vérin

- Prise en charge des retours d'information multiples

- Suivi de l'état du vérin en temps réel

- Dispositifs de sécurité intégrés et programmables

- Service personnalisé pour les applications requérant des BUS de communication

Epandeurs d'engrais ou de semences, engins manipulateurs de grains, moissonneuses-batteuses, tracteurs ou encore tondeuses à gazon, laveuses de sol, balayeuses et matériel de manutention peuvent être équipés du MA4 pour plus de performance.

Caractéristiques Générales

Charge maximale: 2 500 N (poussée/traction)

Vitesse maximale à pleine charge: 4.7mm/s

Vitesse maximale sans charge: 46.1mm/s

Longueur rétractée minimale: ≥ 215mm (selon les options choisies)

Indice de protection (IP): IP69K

Course: 25~1000mm

Signaux de sortie: Mechanical pot., NPN Hall sensors

Tension: 12/24V CC ; 12/24V CC (PTC)

Plage de température de fonctionnement: -40˚C ~ +85˚C

Plage de température de fonctionnement pour une performance optimale: +5°C~+45°C

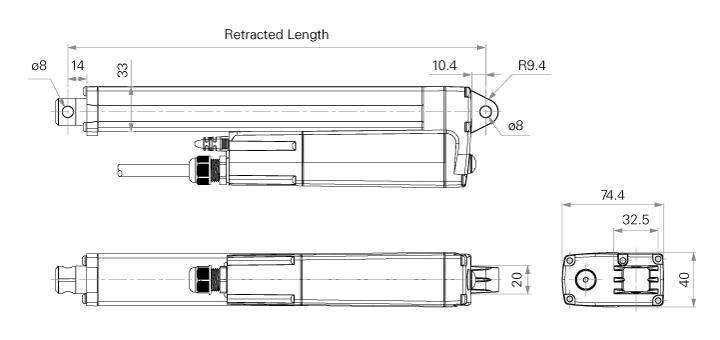

Dimensions standards (mm)

Power And Performance For Your Industrial Equipment - MA Series Electric Linear Actuators

MA Series Industrial Linear Actuators

Industrial Actuators and Related Applications

Téléchargement Documents

- Healthcare: hospital beds, tables, medical chairs, and carts, patient lifts, mobility aids...

- Industry: industrial and agricultural vehicles, automated equipment, intralogistics transport equipment, window opening and ventilation systems...

- Workspace: sit-stand desks, workstations, laboratory benches, control stations, display units...

- Home: sofas, recliners, kitchen furniture...

- Parallel electric actuators: The motor is parallel to the worm gear. Parallel electric linear actuators are usually driven by spur gears, which offer a wider range of gear ratios. These actuators allow for a greater range of loads and speeds but aren’t as quiet as actuators with worm gearing.

- Right angle or "L" shaped electric actuators: The motor is placed perpendicular to the worm gear. A worm gear usually drives L-shaped electric linear actuators. These actuators offer fewer gear ratio choices than spur gear motors but are quieter and offer increased irreversible force.

- In-line electric actuators: The motor is in line with the worm gear. In-line electric linear actuators, therefore, have a longer retracted length. They are usually driven by a set of planetary gears and are specifically designed to fit into tight spaces. However, they have a higher noise level.

- Dual engines: Dual motors operate in two different directions, independently or simultaneously. They are usually driven by gears with a worm wheel and, therefore, offer a quieter movement.

- The electric sliding actuators: Electric slide actuators allow linear movement without the use of an outer tube. The front attachment is linked to the nut, which moves along the worm gear.

- Geared motors: Gearmotors allow the design of economic and versatile systems when combined with one or more worms. Compact, they are usually driven by gears with a worm wheel and are an ideal choice for achieving mechanical synchronization.

- Electric lifting columns: We manufacture lifting columns for industrial, medical, and ergonomic applications. They allow the vertical movement of high loads while maintaining a high level of stability.

- Load to be pushed

- Required speed of movement

- Duty cycle

- Available installation space

- Application environment requirement

An electric linear actuator is an electromechanical device mainly composed of a motor, a set of gears, and a motion mechanism in the form of a worm and tube. It converts the motor’s rotary motion into linear motion by driving the gears and worm gear, By providing linear movement, it can be integrated into any equipment to push, pull, lift, lower, position, or orient a load.

Electric actuators are easy to install and operate. They require minimal maintenance and deliver accurate, efficient, safe, ergonomic, and environmentally friendly movement. These actuators can be easily integrated into industrial, medical, home furniture, or ergonomic desk applications to push, pull, raise, lower, or orient a load. With increasing power and sophistication, they can operate in any direction, gradually replacing hydraulic and pneumatic systems that are considered too constraining or cumbersome.

Thanks to their incredible versatility, electric actuators offer numerous possibilities for movement, enabling the design of ergonomic and comfortable equipment. By adapting to individual needs, they enhance accessibility and ergonomics, promoting easy integration. Electric actuators facilitate a wide range of tasks, enhancing performance and productivity in various activities. This is why they are found in most everyday equipment across diverse applications:

There are many types of electric linear actuators. Actuators, columns, gear motors, and others all have their specificities and their strong points. Discover the list of the different types of actuators that TiMOTION produces and adapts to the needs of equipment manufacturers:

It is important to select an actuator that can meet the requirements of the application. Every application has a list of unavoidable conditions. To choose the right electric linear actuator, you must first consider your application's constraints and technical priorities:

At TiMOTION, technical experts will work with you throughout your project to provide the best solution for your application. With a vertically integrated business model, TiMOTION offers highly customized solutions to meet the unique requirements of various applications, ensuring that the integration of electric linear actuation is seamless and efficient.

TiMOTION travaille exclusivement avec les fabricants d'équipements d'origine (FEOs). Par conséquent, nous ne stockons, ne distribuons ni ne vendons aucun produit à l'unité.

Pour toute question, remplacement ou achat d'un composant individuel TiMOTION, il est nécessaire de contacter le fabricant de votre équipement spécifique. Les composants sont souvent couverts par leur garantie et peuvent être disponibles en stock pour une distribution à l'unité.