2024/10/18

适用于工业应用的电动直线推杆系列

新闻和文章

在当今快速发展的工业环境中,企业所需的设备不仅要功能强大,还要稳定且高效。无论是在农业、制造业或医疗保健领域,对于能承受高强度工作且不易故障的重型设备系统需求,比以往任何时候都要高。

堤摩讯(TiMOTION)作为电动推杆技术的领导者,设计了各式各样的工业电动推杆,以满足各行各业的多样化需求。堤摩讯(TiMOTION)专注于提供可定制、稳定且易于垂直整合的解决方案,其电动直线推杆专为多个领域的各种严苛环境或特殊需求而设计。

堤摩讯(TiMOTION)的电动直线推杆

探索堤摩讯(TiMOTION)的「工业银河系列」,由七种不同类型的电动推杆系列组成,从重型到轻型负载、以及安装尺寸精巧的工业系统需求,都能精确可靠地提供相应的帮助。

-

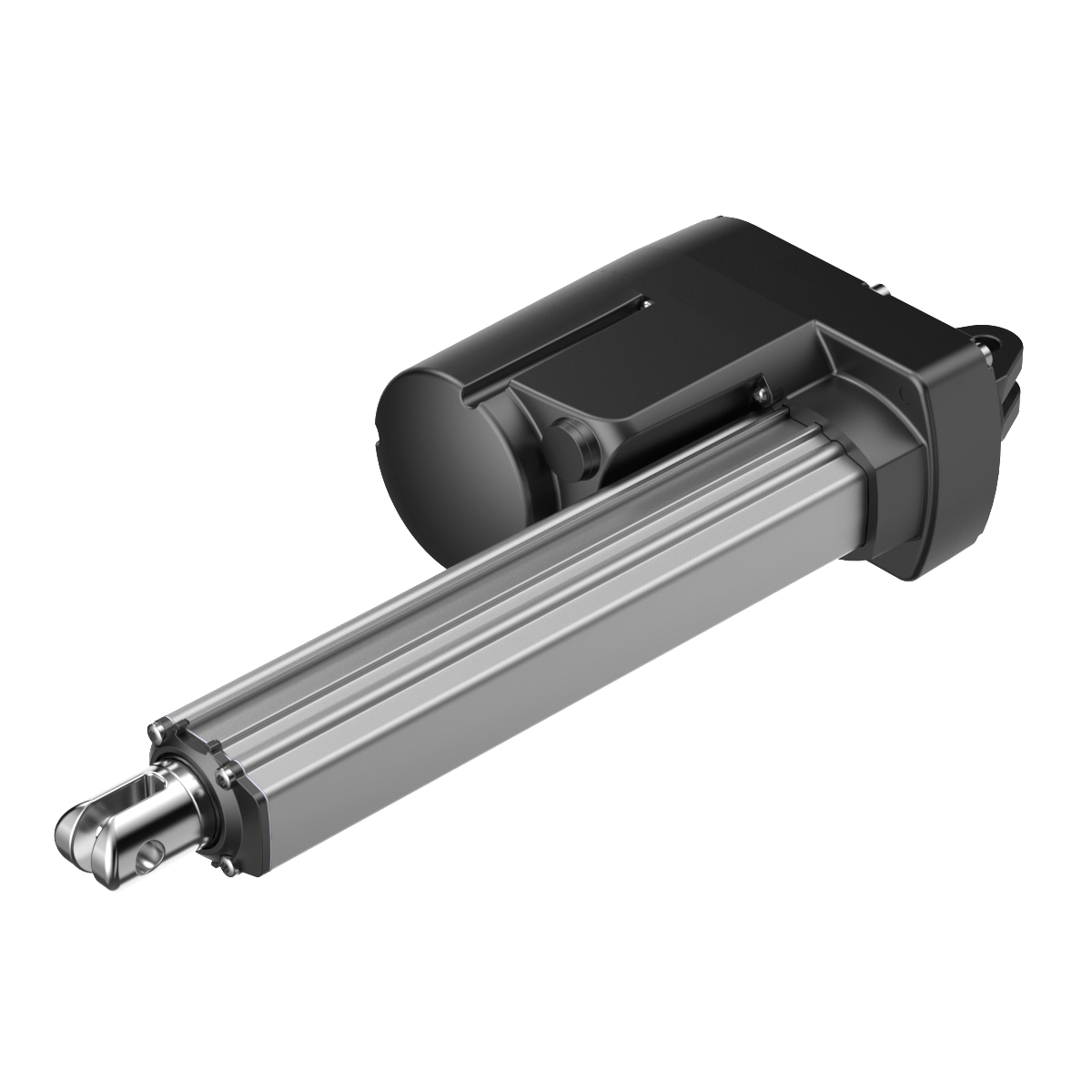

MA系列

MA系列以坚固耐用和强大的性能而闻名,非常适合户外农业和重型工业任务。

|

产品名称 |

||||||

|

最大负载 |

ACME 螺杆:8,000N (推/拉力); Ball螺杆: 4,500N (推/拉力) |

最大负载:8,000N (推力);4,000N (拉力) |

16,000N (推/拉力) |

2,500N (推/拉力) |

3,500N (推力);2,000N (拉力) |

8,000N (推/拉力) |

|

安裝尺寸 |

≥ 行程 + 160mm (ACME 螺杆, 无分压计); ≥ 行程 + 201mm (Ball螺杆, 无分压计) |

≥ 行程 + 131mm |

≥ 行程 + 200mm |

≥ 215mm (依据所选之选项不同) |

≥ 200mm (依据所选之选项不同) |

≥ 行程 + 162mm |

|

輸出信号 |

機械式 pot.、 双霍尔传感器(5-36V 输入或PNP 类型) |

推杆外部信号、机械式Pot.、NPN双霍尔传感器 |

机械式Pot.、 推杆外部信号、NPN双霍尔传感器、 PNP双霍尔传感器 |

机械式Pot.、NPN双霍尔传感器 |

机械式 pot.、NPN霍尔传感器 |

(双)霍尔传感器、机械式 Pot.、可调磁簧开关、NPN双霍尔传感器 |

|

电压 |

12/24/36/48V DC (温控开关); 115/230V AC |

12/24/36/48V DC;12/24/36/48V DC (温控开关) |

12/24V DC;12/24V DC (温控开关) |

12/24V DC;12/24V DC (温控开关) |

12/24/48V DC; 12/24/48V DC (PTC) |

12/24V DC;12/24V DC (温控开关) |

|

IP防護等級 |

IP69K |

|||||

|

操作溫度範圍 |

-40°C~+85°C |

|||||

-

JP系列

JP系列为直线型电动推杆,其外型精巧,俐落,适合广泛的工业应用,从户外农业联合收割机到优雅的凉棚都能提供稳定顺畅的运作。

|

产品名称 |

||||

|

最大負載 |

2,000N (推/拉力) |

4,500N (推力); 3,000N (拉力) |

1,500N (推/拉力) |

3,000N (推/拉力) |

|

安裝尺寸 |

≥ 行程 + 217mm |

≥ 行程 + 289mm |

≥ 行程 + 160mm |

≥ 行程 + 227mm |

|

輸出訊號 |

双霍尔传感器 |

NPN 双霍尔传感器 |

霍尔传感器*2 (5V 输入) |

NPN 双霍尔传感器 |

|

電壓 |

12/24V DC; 12/24V DC (PTC) |

12/24V DC;12/24V DC (PTC) |

12/24V DC;12/24V DC (PTC) |

12/24V DC;12/24V DC (PTC) |

|

IP防護等級 |

IP69K |

|||

|

操作溫度範圍 |

-5°C~+65°C |

-10/-30 ˚C~+70 ˚C |

||

-

VN系列

对于追求功能与美感兼具的客户,VN系列提供优雅美观的解决方案,适合窗户开启器和通风系统。

|

产品名称 |

|||

|

最大负载 |

3,500N (推/拉力) |

500N (推/拉力) |

3,000N (推/拉力) |

|

安装尺寸 |

≥205mm (DC 版本,无T-Smart;依据所选之选项不同); ≥432mm (AC 版本,無T-Smart;依据所选之选项不同) |

≥ 行程 + 189mm |

≥ 行程 + 248mm |

|

输出信号 |

NPN雙霍爾傳感器、 |

NPN 双霍尔传感器 |

双霍尔传感器 |

|

电压 |

12/24V DC、 12/24V DC, PTC、 100~240V AC (50Hz) |

12/24V DC;12/24V DC (温控开关) |

12/24V DC;12/24V DC (温控开关) |

|

防护等级 |

IP66 |

||

|

操作温度范围 |

-15°C~ +50°C |

-25°C~ +65°C |

-20˚C ~ +65˚C |

- SR系列

SR系列的设计注重低噪音的安静运作,且能承受恶劣的天气条件,因此适用于遮阳棚、百叶窗和轻负载工业等应用。

|

产品名称 |

|

|

最大负载 |

4,000N (推/拉力) |

|

安装尺寸 |

≥ 230mm |

|

输出信号 |

机械式 pot. 、双霍尔传感器 |

|

电压 |

12/24V DC;12/24V DC (PTC) |

|

防护等级 |

IP69K |

|

工作温度范围 |

-25˚C ~ +65˚C |

无论您需要的是高强度、多功能性、优雅外观,还是坚固耐用,堤摩讯(TiMOTION)的工业系列都能提供最理想的电动推杆解决方案,帮助提升您的工业项目效能并简化整合流程。

适用于联合收割机的重型电动直线推杆

联合收割机是现代农业的核心,能一次完成收割、脱粒和筛选谷物等重要工作。随着农业技术的发展,这些日常所需的机器背后的技术也在不断进步。传统的气动与液压系统正逐步被电动直线推杆取代,提供了更好的控制性、精准度及环境可持续性。

堤摩讯(TiMOTION)的电动推杆可以调节卷轴位置、管理传动带、控制粮仓盖板、折叠螺旋输送机,以及调节驾驶舱梯子,以确保操作员的便利和安全性。重型电动推杆MA1和MA2在这些应用中表现出色,具有高达8,000N的负载能力,确保上述功能得以精准稳定的执行。

适用于农用喷雾机的重型电动直线推杆

堤摩讯(TiMOTION)的重型电动推杆同样适用于杆架式喷雾机,因为它们可以在关键区域(如喷杆高度、喷嘴定位和喷洒范围)上提供稳定且精准的调节。这种高水平的控制不仅能改善化学物质的滥用,还能降低对环境影响的风险。

堤摩讯(TiMOTION)的MA3和MA6应对严苛的农业任务而设计,具备高效与精确的性能。MA3的负载能力高达16,000N且具备IP69K防护等级,非常适合调节喷杆高度和控制其他重型组件。而MA6具有8,000N的负载能力和IP69K防护等级,适用于精准的喷嘴控制和喷洒器调整。

适用于牧草打包机的重型电动直线推杆

牧草打包机能够将干草、稻草或其他农作物压缩成紧密的包装,以便于处理、储存和运输。

我们的重型电动直线推杆可以在过程中提供精准可靠的控制,增加牧草圆形打包的操作效率。通过调整网或绳索包装程序到压缩草捆,电动推杆确保机器在最严酷的户外条件下也能稳定高效地运作。

MA2电动推杆具有8,000N的负载能力和IP69K防护等级,是压缩重型农作物等重型应用的完美选择。JP4则设计用于较紧凑的负载任务,提供4,500N的负载力,适用于网状或绳索包裹的调整。

适用于撒肥机的重型电动直线推杆

肥料撒播机,通常称为播撒机,是现代农业中不可或缺的工具。这些撒肥机能确保肥料均匀地散布在田间,使土壤更健康、作物产量更高,同时减少不均和浪费。

堤摩讯(TiMOTION)的重型电动直线推杆能提供精准的控制能力,进一步提升撒肥机的性能。我们的电动推杆可以调整撒肥机的角度和范围,以达到最佳的覆盖范围,同时还能调整肥料释放量,使肥料均匀地分布在田间,提高施肥效率。

TA2P重型电动推杆具备3,500N的负载能力和IP66M防护等级,适合在恶劣的户外条件下执行重型撒肥机的任务,精准调整施肥的剂量及喷散角度。

适用于通风系统的重型电动直线推杆

电动直线推杆系统对于优化通风系统非常重要,可以提供精准的气流控制、提高能源效率,并确保在工业环境中稳定可靠的运行。

堤摩讯(TiMOTION)通风系统用的重型电动推杆具有优雅耐用的设计,不仅安装简单且非常耐用,它们经过精心设计,在恶劣环境中仍然可以保持最佳性能。

我们的JP和VN系列专为通风系统设计,外形精巧但同时能提供强大的负载力,以满足现代通风应用的需求。

了解更多重型电动推杆应用,请参考阅读以下文章:

堤摩讯(TiMOTION)重型电动直线推杆的特色功能

无论是用于农业、通风系统,还是工业自动化,我们的重型电动推杆都具有以下设计特点,可提高工作流程效率并处理艰巨的任务:

- T-Smart功能:堤摩讯(TiMOTION)的T-Smart功能将驱动板整合到电动推杆中,允许定制配置、即时监控和总线通讯,无需外部控制盒,简化了系统的组装和性能。了解更多关于T-Smart智能电动推杆的资讯。

- 高负载能力:堤摩讯(TiMOTION)的电动推杆专为处理最艰难的任务而设计,负载范围从500N至16,000N,适合各种严苛的应用环境。

- 易于安装:为了融入现有系统,简洁的设计使电动推杆易于安装,减少停机时间,确保从一开始就能顺利运行。

- 低维护成本:与传统液压系统相比,堤摩讯(TiMOTION)电动推杆的主要优势之一在于其较长的生命周期和低维护需求,无需更换油液或复杂的液压系统,大幅降低长期运营成本。

- 定制IP防护等级:堤摩讯(TiMOTION)电动推杆具有多种IP防护等级,最高可达IP69K,能提供防尘、防污和防高压水柱喷射的保护,适用于暴露在外的环境。

在选择重型电动直线推杆时,评估负载能力、速度和环境条件等因素至关重要。

首先,根据机械任务确定所需的负载能力。举起或推动大型组件等重型应用时,需要更高的负载能力。

接着,考虑速度——过快会导致磨损,过慢则可能影响效率。此外,根据您的电动推杆选择适当的IP防护等级,如防尘、防潮或恶劣环境条件的保护。

如需更多有关电动推杆的选型指导,请参考以下文章:

在堤摩讯(TiMOTION),我们提供多种可客製化的重型电动推杆及配件,专为满足各式特定的工业需求所设计。如果您不确定哪种电动推杆适合您的专案,请联络我们的专家,我们将为您提供量身订做的建议,协助您选择最适合的应用推杆。

今天就联繫我们!

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)