2023/04/03

10 Reasons To Choose Electric Linear Actuators

News and Articles

| Contents |

|

Why choose electric linear actuators for your equipment design? |

| 1. Programmable |

| 2. Accurate |

| 3. Customizable |

| 4. Safe |

| 5. Synchronizable |

| 6. Sustainable |

| 7. Compact |

| 8. Maintenance free |

| 9. Energy efficient |

| 10. Ergonomic |

A sustainable alternative to hydraulic systems, electric linear actuators offer many benefits to your engineering projects. Discover the list of 10 good reasons to adopt electric linear actuators for your equipment development!

The need for innovative equipment is constantly increasing to meet ever higher technological requirements. Safety, speed, precision, ergonomics, and functionality... Manufacturers and consumers are always looking for the latest innovations that will make their lives easier and enable them to be more productive and efficient.

Why choose electric linear actuators for your equipment design?

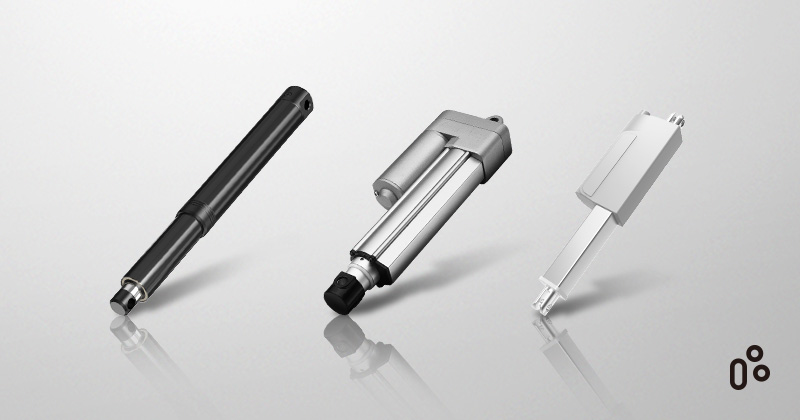

Electric actuators are used in all product development projects. Whether it is a linear actuator, a lifting column, or a gear motor, electric actuators can be easily integrated into any industrial, medical, domestic, or ergonomic application, in order to push, pull, raise, lower or orient a load. Increasingly powerful and sophisticated, they can operate in any direction and are gradually replacing hydraulic and pneumatic systems, which are considered too constraining or cumbersome. Discover all the benefits of electric linear actuators.

List of the 10 advantages of electric linear actuators

1. Programmable

Electric linear actuators work with an electronic control box (external or integrated). Equipped with software, it allows the control box to manage and organize the different movements the application must perform. Thus, many parameters can be precisely programmed, such as speed, stroke, safety functions, or motor synchronization.

2. Accurate

An electric actuator offers a high level of precision in both movement and control. It provides smooth, jerk-free movement with a soft start and stop function. In addition, it allows precise control adapted to your most specific needs. For example, it is possible to program variable speeds within the stroke if your application requires it, as well as other customizable parameters.

3. Customizable

The electric actuator is customizable to a precise specification. Whatever your application needs, it is possible to define the speed, stroke, type of attachment, and many other parameters to create the right electric motion system for your project.

4. Safe

Several safety options can be integrated into an electric actuator to ensure its lifetime and protect users and equipment from damage. There are several safety features that suit different types of needs:

- The thermistor (PTC), known as the positive temperature coefficient, switches off the motor at a specific temperature to prevent overloads that could damage the actuator.

- The safety nut, integrated into the actuator supports the load in case of breakage or failure of the spindle nut.

- The "push only" function prevents a foreign element from damage or crushed when the mechanism retracts.

- In case of emergency, the mechanical quick-release system allows the actuator to manually disengage and retract quickly.

- The overload clutch allows the motor to be disengaged when a specific preset load is reached.

To learn more about the safety options of TiMOTION electric actuators, check out our dedicated article!

5. Synchronizable

Thanks to position sensors, two or more electric linear actuators can operate a synchronized movement. The sensors will provide feedback to the control box, which will adapt the speed of the different motors for perfectly synchronized movement. Synchronization is ideal when the load requires several motors to operate with smooth and stable motion.

TiMOTION offers several different position sensors for electric linear actuators:

- Hall effect sensors measure a magnetic field that determines the motor’s direction of rotation and counts the number of motor revolutions.

- The potentiometer is a sensor that retains the position of the actuator even when the power is off. Thus, a reset is not necessary.

- The Reed sensor is a magnetic position sensor. It allows for functionality such as variable stroke adjustment.

To learn more about TiMOTION electric actuator sensors, check out our article!

6. Sustainable

Electric linear actuators have a long service life. Its components are designed to protect internal mechanisms and withstand environmental stress. The motion mechanisms have an applied lubricant that reduces friction to keep the operating temperature lower. Lubrication also reduces noise and vibration while preventing premature wear of the actuators, increasing their longevity.

TiMOTION offers additional options to further ensure the reliability of its devices. Most of our electric linear actuators can be equipped with various levels of IP protection that allow them to withstand external solid and liquid contaminants. Some of our industrial electric actuators can achieve a IP rating of up to IP68 or IP69K, which is essential to endure extreme industrial environments.

For more information, see our article on protection ratings for electric actuators.

7. Compact

Thanks to their compact design, electric linear actuators can be easily integrated into any type of equipment. From large industrial machines to medical equipment and small furniture, they are ideal for designing complex systems with multiple movements. This compact design offers product engineers great versatility in integrating multiple electric actuators into a single piece of equipment, even when installation space is limited.

8. Maintenance free

An electric actuator operates without hoses, fluid injection, or air compressors. This makes it an excellent alternative to hydraulic or pneumatic actuators that require regular maintenance. With no leaks, the electric actuator requires no maintenance and provides a clean, easy-to-use solution. These features are essential when the mechanism is out of reach or difficult to access.

9. Energy efficient

The electric linear actuator consumes little energy compared to hydraulic and pneumatic systems. Most TiMOTION control boxes have a standby power consumption of less than 0.1 W.

10. Ergonomic

Thanks to their incredible versatility, electric actuators offer many possibilities of movement and allow the design of ergonomic and comfortable equipment. By adapting to individual needs, they improve accessibility and promote easy integration. They facilitate many tasks and bring performance and productivity to any activity. That's why they are found in most everyday equipment, regardless of the application:

- Industry: industrial and agricultural vehicles, automated equipment, intralogistics transport equipment, window opening and ventilation systems...

- Medical: beds, tables, medical chairs, carts, patient lifts, mobility aids...

- Home furniture: armchairs, recliners, kitchen furniture, desks...

- Professional furniture: sit-stand desks, workstations, laboratory benches, control stations, display units...

Why choose TiMOTION electric linear actuators? For more than 15 years, TiMOTION has been supporting its customers in their product development projects with complete turnkey solutions.

Do you want to start an engineering project with personalized support and a premium service? Contact our local sales department!