2024/11/13

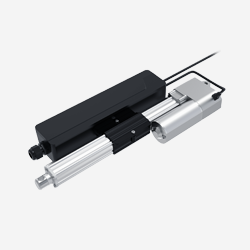

12V Linear Actuators: Power from 1000N to 10000N

Nachrichten / Artikel

TiMOTION is at the forefront of electric actuator technology, delivering innovative solutions that drive efficiency, precision, and flexibility across various industries. Our portfolio primarily includes electric linear actuators powered by 12V and 24V direct current (DC). Additionally, select models are available in 36VDC, 48VDC, and 110-240VAC configurations to meet specific operational needs.

Our versatile 12V linear actuators support loads ranging from 1,000N to over 10,000N, with numerous customization options. These actuators are ideal for demanding applications in healthcare, furniture, and industrial environments.

Below, you’ll find a quick overview of 12V electric linear actuator models suited to different load capacities, helping you choose the right solution for your project design.

12V Linear Actuators for 1,000N to 2,000N Loads

- TA2, TA42, JP5: Designed for low-load applications with capacities from 1,000N to 1,500N (up to 337 lbs).

- TA38M, JP3, TA2PAC: Built for medium-force applications, supporting loads up to 2,000N (449 lbs).

Despite their lower force capabilities, these models stand out for their compact design and easy installation, making them perfect for use in space-constrained environments.

TA2 |

TA42 |

JP5 |

|

|

|

|

|

|

TA38M |

JP3 |

TA2PAC |

|

|

|

|

|

|

12V Linear Actuators for 2,000N to 3,000N Loads

The TA9, MA4, VN3, and JP6 series are designed for moderate load handling applications, supporting capacities from 2,000N to 3,000N (up to 674 lbs). These models are ideal for use in furniture and medical equipment, where a balance of strength and precision is essential.

TA9 |

MA4 |

VN3 |

JP6 |

.jpg) |

|

|

|

|

|

|

|

12V Linear Actuators for 3,000N to 4,000N Loads

For applications requiring higher force output, TiMOTION offers the TA2P, MA5, VN1, TA29AC, TA43, and SR1 models, which deliver both strength and precision within the 3,000N to 4,000N range (up to 899 lbs). These actuators are well-suited for home furniture applications, providing enough power to support a person’s weight on beds or sofas during various reclining and rotational movements.

TA2P |

MA5 |

VN1 |

|

|

|

|

|

|

TA29AC |

TA43 |

SR1 |

|

|

|

|

|

|

12V Linear Actuators for 4,000N to 5,000N Loads

The TA16, JP4, and TA31QR series deliver up to 5,000N of force (1,134 lbs), making them ideal for industrial applications. These actuators often feature high IP ratings, optional Hall sensors, and low-noise operation to meet demanding environmental standards.

TA16 |

JP4 |

TA31QR |

|

|

|

|

|

|

12V Linear Actuators for 5,000N to 8,000N Loads

Electric linear actuators with lifting capacities up to 6,000N (1,348 lbs) are built for heavy-duty environments. The TA29 and TA49 series offer compact solutions for medical applications such as patient hoists and surgical tables. For industrial use, the MA1, MA2, and MA6 series excel in rugged environments with IP69K-rated protection.

TA29 |

TA49 |

MA1 |

MA2 |

MA6 |

|

|

|

|

|

|

|

|

|

|

12V Linear Actuators for Loads above 8,000N

Built for durability and high-speed performance, 12V linear actuators with capacities above 8,000N offer advanced features. The TA12, TA23, and TA37 series excel in high-load medical applications, featuring IP66W ratings, Hall sensors for precise position feedback, and manual release options for emergencies.

For extreme conditions, the MA3 series delivers up to 16,000N of force and incorporates T-Smart technology for enhanced performance.

TA23 |

TA12 |

TA37 |

MA3 |

|

|

|

|

|

|

|

|

Key Specifications of 12V Linear Actuators

The technical specifications of an electric linear actuator determine its performance. Below are the essential factors to consider:

-

Voltage and Power Requirements

To ensure compatibility with power sources, the actuator’s voltage must match the supply of the system. Undervoltage may cause the actuator to underperform, while overvoltage risks damaging equipment.

Always refer to the machine’s manufacturing specifications to determine the correct voltage requirements. Most of TiMOTION’s actuators run on DC power, and for added flexibility, TiMOTION offers control boxes that convert DC to AC power, enabling easy integration with standard AC outlets.

-

Load Capacity and Speed

The load capacity and speed of 12V actuators depend on factors such as torque, gear ratio, and screw type:

- Torque: The motor’s rotational force, which determines the actuator’s ability to move heavy loads.

- Gear Ratio: A higher ratio increases torque but reduces speed, while a lower ratio allows faster movement at the cost of reduced force.

- Screw Type: Lead screws offer high load capacity but operate at slower speeds due to friction. Ball screws reduce friction, enabling faster movement.

See the full article: Load And Speed Characteristics Of An Actuator

-

Duty cycle

The duty cycle refers to the ratio of operational time to rest time, expressed as a percentage. A higher duty cycle allows for longer operation without rest, making it ideal for continuous or frequent use. Actuators equipped with parallel motors and spur gears tend to offer superior duty cycles, enhancing performance in demanding applications.

How to Choose the Right 12V Linear Actuator

Selecting the right 12V linear actuator requires evaluating your application needs, considering environmental conditions, and comparing available models to ensure the best fit.

Here’s a quick guide to help you make the right choice:

-

Assessing application needs

When choosing an actuator, focus on three essential factors: load capacity, speed, and stroke length.

- Load Capacity

or light-duty tasks like furniture adjustments, capacities between 1,000N and 2,500N are suitable for reclining mechanisms. Industrial applications may require up to 10,000N for heavier loads.

- Speed

Speed, measured in millimeters per second (mm/s), affects how quickly the actuator completes tasks. 50 mm/s at no load is typically fast enough for quick adjustments, while speeds below 10 mm/s are considered slow. Ensure the actuator’s speed aligns with your application’s requirements.

- Stroke Length

Stroke length refers to how far the actuator can extend, measured in millimeters (mm). Longer strokes require more space for installation, so check your available space carefully.

-

For a detailed guide, check out our full article on choosing electric actuators. Understanding Environmental Considerations

Environmental conditions play a crucial role in actuator selection, particularly regarding IP ratings (Ingress Protection) for dust and water resistance.

- For indoor applications with minimal moisture exposure, an IP54 rating is usually sufficient.

- In outdoor or harsh environments, where dust and water exposure is high, choose actuators with IP69K protection.

After identifying your application’s requirements, compare models based on features that align with your industry.

- Medical Applications: Actuators like the TA23 and TA38M comply with IEC 60601 safety standards and offer quick-release functions for patient safety.

- Furniture Applications: Actuators such as the TA16 and TA25 provide quiet operation and compact designs, ideal for adjustable beds and sofas.

- Industrial Applications: Models like the JP5, MA3, SR1, and TA2P are built for durability and high load capacity, with high IP ratings for rugged environments.

Looking for Other Specs? Discuss Your Project with TiMOTION

Whether you need a waterproof linear actuator, a heavy-duty actuator, or other customized options, TiMOTION specializes in creating 12V linear actuator solutions tailored to your specific requirements. Our process begins with a thorough understanding of your application environment, specifications, and installation needs.

If you seek customizations such as voltage, force, IP ratings, or mounting options, we’ll collaborate with you to explore all possibilities.

Once the details are finalized, we proceed to sample production, followed by rigorous testing and necessary adjustments to ensure everything is just right. Our goal is to deliver a solution that not only meets but exceeds your expectations.

Do you have specific specs in mind, or do you need assistance determining the best options for your project?

Reach out to TiMOTION today. We’re here to guide you from initial concepts to final adjustments.